ERB Steam Solutions...since 1975

Focusing on Thermal Energy Integration, we advocate best practices while optimizing thermal systems and maximizing performance, service-life and economy. Personal Services include Expert Witness, Consulting, Program Development, Steam System Assessments, Audits, Implementation Support, and Engineering Design for Steam and Heat Transfer systems. Business Development for Manufacturers, including Technical Training for End Users, Sales Training for Distributors and Wholesalers.

ERB Steam Website

- Richard G. Bockwinkel Bio

- Ven V. Venkatesan Bio

- Richard G. Bockwinkel LinkedIN

- Expert Witness

- ASHRAE Auditing

- Steam Trap Management

- Premier Specialty Products

- SLATES: Asset Monitoring

- AirPIPE Compressed Air

- ERB & Associates, Inc. Website

- ThermaXX Insulation Solutions

- Superior Products (Insulation Coatings)

- AQUApipe SS Condensate Piping Systems

Monday, January 16, 2023

Representing

Saturday, September 18, 2021

Friday, July 16, 2021

Plumbers, Pipe-fitters and Steam-fitters

Plumbers are not Pipe-fitters. Each has specific skill sets.

Steam Fitters...have specific skill sets that are NOT akin to Pipe Fitting and Plumbing.

POINT...if it's a STEAM job...don't hire any outfit that does not provide TENURED, SKILLED steam fitters.

Best Practices with steam fitting is not something to lay off on a jack of all trades.

Monday, July 27, 2020

Slates: Equipment Monitoring

Slates: Companion Tags

Slates™ are customized anodized aluminum smart tags that are fixed to your steam trap or any desired component. Every Slate tag is laser etched with a unique QR code, and a unique ID number, that you can easily scan using the Slate Pages app, available for iOS. Upon scanning a Slate tag with the Slate Pages app, you will be presented with your steam trap’s or any equipment's up-to-date information.https://youtu.be/1I4BgC-9YYI

The Slate Pages app empowers you to track and explore any desired information using custom information fields (text, URL, photos, dates, location & more). For example, Slates fixed to steam traps commonly feature the following maintenance information fields:

- Component Name (e.g. Steam Trap #12)

- Component Manufacturer/Model (e.g. Armstrong Series 811)

- Photo of Component

- Map/Location of Component

- Date of Last Inspection/Service

- Copy of Operating Manual

- Purchase or Install Date

- Warranty Expiration Date

- Maintenance Journal

Your Trap information is also available on a Web Portal!

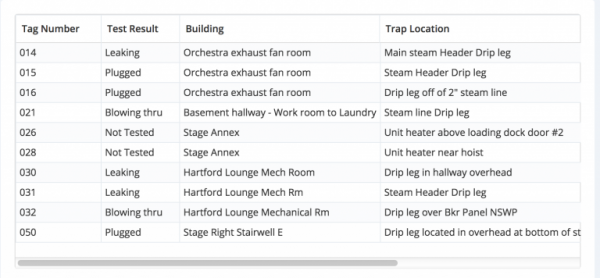

Get an overview of all of your steam traps & other industrial components in an instant by tagging your entire facility with Slates. Sort your steam traps by any field such as last inspection date, manufacturer/model, or component name for easier decision making.

For those facility managers with a large campus, with a number of buildings, Slates allows you to capture a GPS coordinate and gives you the ability to sort and color your failed traps in a map view. (red=failed / green=good)

The Slate Pages app was designed to make information about your steam traps more easily accessible. Your team can access, view, & edit any information with the proper user permissions, set by the account owner.

If you have a steam trap survey file that you would like to incorporate SLATES...send us the data in Excel or CSV format and we will generate a presentation to illustrate the merits of SLATES for your specific facility.

To learn more about Slates Steam Trap Tags contact Rick Bockwinkel at Bock@ERBSteam.com, or call 913-579-7688.

Wednesday, July 22, 2020

Steam Trap Surveys. Steam Trap Management.

STEAM TRAP SURVEYS...an Energy Conservation Measure (ECM) with compelling paybacks.

Some states offer rebates and incentives that further improve cost recovery while boosting heat integration at your facility.

click here --> Rebates and Incentives Offerings

Sunday, September 1, 2019

Root Cause of Failure: Steam Specialty Equipment

Monday, April 1, 2019

STEAM TRAP SURVEYS...Keeping you on the path of peak energy optimization.

- Site-wide steam trap study (more deliverables than a performance survey)

- Audit of Specifications

- Audit of Standards

- Audit of Purchases/Warehouse stock

- Development of integrated solutions

- Baseline

- Benchmark

- Audit

- Pass/Fail

- Performance

- Turnkey

Saturday, June 2, 2018

OSHA Personnel Protection Standards... BURN Prevention

Friday, January 12, 2018

Heat Exchangers Hammering? Tube Bundles Fouling and Failing?

Thursday, November 2, 2017

Tuesday, August 15, 2017

Monday, March 3, 2014

Steam Trap AUDITS are not Steam Trap SURVEYS

Sunday, March 2, 2014

Wednesday, February 19, 2014

Best Practices: Steam Control Valve Installation Illustration

Friday, February 14, 2014

When you say Steam...what do people think?

People invariably think of steam as something for cleaning or ironing...or running a locomotive. But steam is much more pervasive than that! Steam is the single most widely used DERIVED energy source on the planet.

Get the most out of it...and hone your competitive advantage.

Wednesday, January 11, 2012

Monday, June 27, 2011

A Primer on BOILER PRIMING / Carryover Problems

There are a number of solutions that can readily mitigate this.

Contact ERB and Associates, Inc.

Richard Bockwinkel by phone: 913.579.7688 or eMail: Bock@erbsteam.com.

The PRIMER...In a boiler steam bubbles are continually bursting at the steam water interface and ejecting boiler water drops into the steam space.

The PRIMER...In a boiler steam bubbles are continually bursting at the steam water interface and ejecting boiler water drops into the steam space.The steam also drags the surface of the boiler water towards the steam outlet so that the water level at that point can be higher than elsewhere, depending on the positions of the level controls this may cause the feed pumps to deliver water and thus raising the water level further.

As the water level is raised the volume of the steam space is decreased, the speed of the steam across the surface is increased drawing foam and water droplets towards the steam outlet. A sudden increase in steam demand can cause a slug of boiler water to enter the steam outlet. This is known as priming. Operation of the boiler below its design pressure will also produce a similar effect.

As the water level is raised the volume of the steam space is decreased, the speed of the steam across the surface is increased drawing foam and water droplets towards the steam outlet. A sudden increase in steam demand can cause a slug of boiler water to enter the steam outlet. This is known as priming. Operation of the boiler below its design pressure will also produce a similar effect.Tuesday, February 22, 2011

The FIRST ALL STEAM TURBINE STATION in AMERICA 1903

And in the foyer, in the VISITOR log that is on DISPLAY...see below...the name...

Thomas Edison, Inventor.

Unfortunately there was no room on that page for me to sign in ;-)

Tuesday, August 3, 2010

Pre-Insulated Tubing EQUALS Instant Steam/Condensate "PIPING"

The beauty of pre insulated steam tubing is its ease of installation; not to mention that you can color code fluid transfer lines...steam, condensate, compressed air, nitrogen and so forth...

The practicality is impressive. There are less fittings required; thus less leak points...less time to install...and less contamination potential from thread sealant materials migrating into the fluid space.

Sunday, February 28, 2010

90.9% of all Electrical Power is DERIVED from STEAM

Monday, February 15, 2010

Is this steam trap failed?